Magnetic stirrers are staples in many labs, and are useful in a variety of mixing and dispersion applications. However, they don’t come without their problems, and it’s common to have to troubleshoot various issues while using a magnetic stirrer.

In this post, we take a look at the problems you might come across and steps you can take to overcome them.

Common Issues With Magentic Stirrers

Some of the main issues you’ll find with an overhead stirrer are:

- Uncoupling of the bar: The magnetic stir bar becomes uncoupled from the drive magnet.

- The bar becoming stuck: The bar stops spinning, for example, in a viscous sample or in a mixture with lumps of agglomerated solids.

- Insufficient mixing: You may find that your sample is insufficiently mixed; it’s common for the middle of the sample to be mixed well, with the outside and top remaining heterogeneous.

Ways to Solve Magnetic Stirrer Issues

The above issues could be caused for a variety of reasons. For example, insufficient mixing could be due to using the wrong stir bar, a stirrer that isn’t powerful enough, or the wrong type of equipment entirely.

Below are some things you can try to fix your issue.

- Increase the speed slowly

- Use the correct stir bar

- Try switching vessels

- Use a unit with more power

- Consider using an overhead stirrer

Let’s look at those in more detail:

1. Increase the Speed Slowly

A common cause of uncoupling is increasing the speed too fast. This can lead to spinout where the bar loses its coupling with the magnet and migrates from its central position in the vessel. The bar might stop spinning entirely or move erratically until the speed is decreased.

The simple solution to this is to try ramping the speed up slowly. Aside from preventing spinout of the stir bar, speed ramping can decrease the risk of your sample splashing. Many stirrers, including Troemner Professional Round Top Hotplate Stirrers (below left), and Jeio Tech MS Magnetic Stirrers (below right) come with a slow start (speed ramping) feature.

2. Use the Correct Stir Bar

There are lots of different options when it comes to stir bars and using the wrong one could result in problems, including uncoupling and insufficient mixing.

Different shapes of stir bar are designed for different purposes. For example, a triangle (prism) bar provides lots of turbulence and can act as a scraper to help dissolution or prevent sedimentation.

Some stir bar shapes are ideal for certain vessel types and help to prevent the bar uncoupling or becoming stuck. For example, spherical (ball) stir bars are typically used in tubes and vials for low-volume samples.

Slide round bars have a pivot ring going around the center of the bar. The design enables them to maintain an optimal position in a vessel with a curved or uneven bottom. The ring reduces vibrations and wear, and lowers the amount of friction resulting from contact between the bar and the vessel.

Prism, ball, and pivot ring stir bars.

Aside from choosing the correct shape of stir bar, you need to ensure you have the right size. Of importance here is the size of the magnet inside the stirrer, often referred to as the drive magnet.

To avoid spinout, ideally, the stir bar should be roughly the same length as the drive magnet. For longer magnets, the maximum speed may be need to be lowered, as more drag is produced without proportionately stronger magnetic coupling.

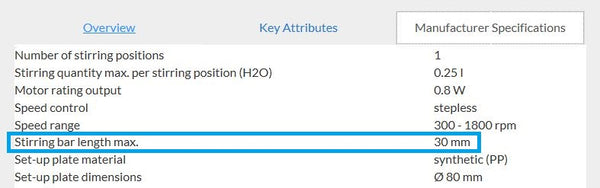

Some manufacturers will advise you of the recommended maximum length of stir bar to use with a specific model.

Manufacturer specifications for an IKA Topolino magnetic stirrer.

You can purchase sets of stir bars of a range of sizes, such as this one:

IKA’s RS 1 Set of magnetic stirring bars.

3. Try Switching Vessels

Instead of switching up the stir bar you’re using, you may want to consider changing your vessel, if possible. For example, if you’re limited to using a regular round stir bar, you should be using a vessel with a flat bottom.

Arched-bottom vessels are more difficult to work with. First, it’s difficult to position the stir bar correctly, although using a bone stir bar can help. Second, in an arch-bottomed vessel, the distance between the stir bar and the drive magnet is decreased, which makes for poorer coupling. For this reason, it’s also better to choose a vessel with a thin bottom.

Also, pay close attention to the positioning of the vessel on the stirrer plate. It needs to be in the center of the plate for optimal coupling and to prevent the bar catching on the side of the vessel.

If you’re working with a vessel that isn’t is contact with the plate, for example, a test tube or round-bottomed flask, ensure that it’s as close to the stirrer plate as possible.

4. Use a Unit With a Stronger Magnet

Magnetic stirrers are equipped with an internal drive magnet, the size and strength of which limit the capabilities of the stirrer. If you’re using a unit with a relatively small, weak internal drive magnet with too large a volume or too viscous a substance, then you could run into issues, including the bar becoming stuck and insufficient mixing.

You will typically find the maximum volume a stirrer can be used for within the manufacturer's specifications. For example, for the IKA Topolino, the maximum volume is 250 mL, and for the Scilogex MS-P Series Magnetic Stirrer, it’s 3 L. However, unless stated otherwise, these numbers are based on samples that have a similar viscosity to water.

The IKA Topolino and the Scilogex MS-P Series Magnetic Stirrer.

5. Consider Using an Overhead Stirrer

Magnetic stirrers aren’t suitable for all types of mixing applications. If you’ve covered the points above and are still seeing issues, then an overhead stirrer might be more suitable for your task.

We’ve discussed the decision between a magnetic stirrer and an overhead stirrer in depth in a recent post, but some of the main considerations include the volume and viscosity of the samples you’re mixing.

For example, if the product is too viscous, the magnetic coupling between the bar and the drive magnet won’t be strong enough to overcome the resistance of the viscous material.